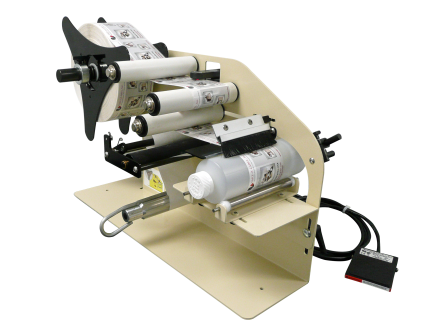

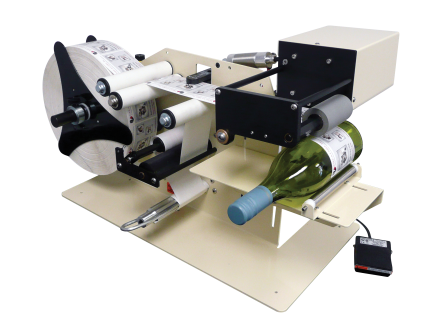

Bottle Label Applicators

Bottle Label Applicators

Desktop or Inline Bottle Labeling Solutions

Whether you're searching for a budget-friendly semi-automatic desktop label applicator or a fully integrated inline solution, we have the perfect options for small and medium-sized businesses. Our range is designed to meet diverse labeling needs, ensuring efficiency and ease of use. With our reliable applicators, you can streamline your operations without compromising quality. Explore our solutions tailored to elevate your business today!