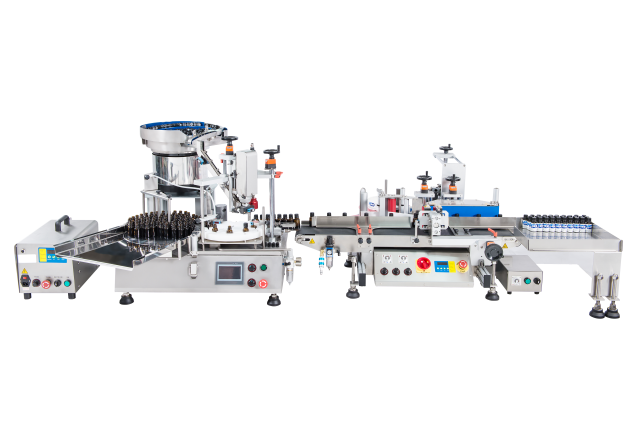

Compact Filling Line

CFL200 Liquid Filling Line Machine: At a Glance

Quickly and confidently set up a bottle filling line in a small space. Start a more efficient production run for your business with this compact liquid packaging line machine. Fill up to one bottle per second with assistance from automated processes. Compatible with a wide range of liquid products.

- Volume range: 5 - 240ml per cycle

- Filling speed: Average 20-30 bottles/min *Up to 60 pcs/min for mininum fill volume

- Filling accuracy: +/-1%

or

(866) 520-3248

Bottle Filling Machine Details

A bottling line doesn’t have to be extremely complicated or take up a substantial amount of space. Looking for a small-scale filling machine that you can count on? You can fill many types of products with this bottling line equipment.

The Compact Filling Line combines a bottle feeder, filler, capper, and label applicator into one single production line. This liquid filling and capping machine can do it all, helping you get your products to customers more quickly.

Our bottle filling production line is ideal for flexible, small-scale work with low viscosity liquid filling. It includes:

- Feeding Station with Rotary Table

- Tabletop Gear Pump Filling Machine

- Automatic Cap Torquing Machine (with optional cap feeder)

- Advanced Tabletop Labeling Machine

The CFL200 is equipped with an advanced and precise detecting system that leads to a simple and effective result: No bottle, no filling; No cap, no capping.

An AC motor controls the capper module to reach the required torque value for proper tightening on each container. This liquid filler includes a counting system for updating filling progress.

Optional filling system features:

- Auto Cap Feeder

- 3 Wheel Capping Solution (for multiple style caps)

- Hot Code Printer for Label Applicator

- Accumulating Table or Catch Tray

- Tamper Banding Heat Tunnel with manual sleeve placement

| Fill Volume | 5 – 240ml per cycle |

|---|---|

| Capacity | up to 60 bottles /min depending on fill volume |

| Construction | Liquid contact parts are made of SUS#316 Stainless Steel. Frame and main components are made of SUS#304 Stainless Steel |

| Power Supply | 110V AC, 60HZ |

| Air Supply | 5cfm @ 90 psi (30-gallon compressor minimum recommended) |

| Control | PLC + HMI color touch screen control |

| Bottle Diameter | 16-54 mm |

| Bottle Height | 30-160 mm |

| Minimum Label Size | 10 mm (L) * 10 mm (H) |

| Maximum Label Size | 300 mm (L) * 100 mm (H) |

| Label Core Size Diameter | (ID) 75 mm; (OD) 300 mm |

| Accuracy | +/-1% |