How a box tape machine can cut packing time in half

For small and medium-sized businesses, packaging is an essential yet time-consuming process. Whether you're shipping products to customers, preparing orders for retail, or keeping up with increasing demand, efficiency in packaging operations can make all the difference. Unfortunately, relying on manual taping slows down production, increases labor costs, and introduces inconsistencies that can lead to damaged shipments.

The good news? A box tape machine can dramatically speed up the packaging process, improving both productivity and product security. With this equipment, businesses can pack more efficiently, reduce waste, and free up valuable employee time to focus on other critical tasks.

At Cleveland Equipment, we specialize in economically priced, semi-automated packaging solutions designed to help businesses scale faster, smarter, and more cost-effectively. A box sealer machine can transform your packaging operations, saving you time and money.

What is a taper machine?

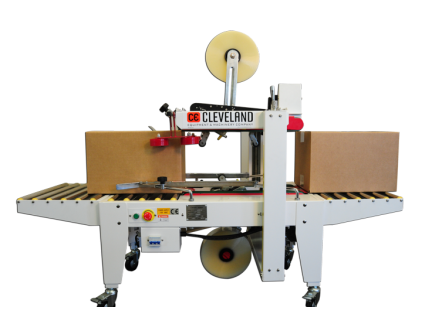

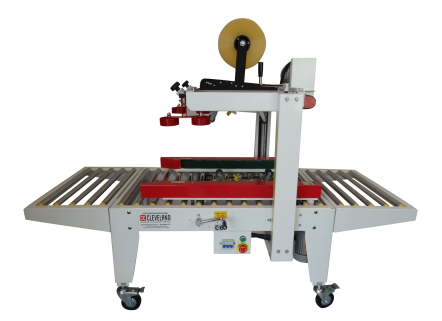

A taper machine, also known as a box taper, carton sealer, or case sealer machine, is a piece of equipment designed to efficiently apply carton sealer tape to shipping boxes. These machines improve the process of taping cardboard boxes, ensuring consistent, secure seals while eliminating the need for slow, manual labor.

Box taping or glue solutions

For over 25 years, Cleveland Equipment has been a trusted provider of case tapers and box sealing machines. Our extensive experience means we know exactly what businesses need to increase efficiency and improve packaging consistency. We stock our tapers, provide full-time support, and offer a one-year warranty on all our units. Whether you're operating on a single shift or running 24/7 production, we have a taper solution for you.

Our case tapers come in different models to suit varying levels of production, including:

- Entry-level box tapers for small businesses with lower output needs

- Semi-automatic case sealers for mid-sized operations

- Fully automatic carton sealers for businesses scaling up to high-speed production

Regardless of your production level, our box sealer machines provide a cost-effective way to streamline operations, improve packaging quality, and reduce labor-intensive tasks.

How can I use a taper machine?

Using a carton sealer is straightforward and significantly more efficient than manual taping. Here’s how a box machine can be integrated into your packaging process:

- Box Preparation – Employees assemble the box and place the products inside.

- Feeding the Box – The operator places the open box onto the machine’s conveyor system.

- Automatic Taping – The case sealer machine applies carton sealer tape to both the top and bottom of the box, ensuring a secure closure.

- Final Packaging – The sealed box moves down the line, ready for labeling and shipping.

For example, semi-automatic carton sealers are great to have available if you need to pack boxes of different sizes. With these, you can quickly adjust the machine to the width and height of the box you're sealing and it will apply the same amount of tape to each box.

This process eliminates the inconsistencies of manual taping, reducing wasted tape and ensuring a professional, uniform look across all shipments. Plus, by integrating a box taper into your existing packaging workflow, you’ll speed up order fulfillment while maintaining product protection.

What are the benefits of a taper machine?

1. Increased efficiency and speed

Manual taping is one of the biggest bottlenecks in packaging. Employees must measure, cut, and apply tape by hand—slowing down production and increasing labor costs. A box tape machine can seal boxes in a fraction of the time it would take a worker to do it manually. You can process twice as many orders in the same timeframe simply by adding a box sealer machine to your workflow.

2. Reduced labor costs

A case taper allows your team to focus on higher-value tasks instead of repetitive sealing. Instead of dedicating multiple employees to taping boxes, a single operator can manage a carton sealer—leading to significant labor savings.

3. Consistent and professional seals

Manually applied tape can be inconsistent—sometimes too loose, sometimes too tight, and often uneven. Poorly sealed boxes can lead to damaged products, customer complaints, and increased returns. A box sealer ensures every package is sealed uniformly and securely, giving your shipments a clean, professional appearance and protecting them during transit.

4. Minimized tape waste

When employees tape boxes manually, they often overuse tape, leading to unnecessary material costs. A carton sealer machine applies the exact amount of tape needed, reducing waste and cutting down on supply costs over time.

5. Scalability for growing businesses

For businesses looking to scale, efficiency in packaging is crucial. A box tape machine allows operations to keep up with higher order volumes without increasing labor costs. Whether you're shipping 50 boxes a day or 5,000, a carton sealer ensures seamless growth while maintaining packaging consistency.

Examples of taper machines: hear from our customers

At Cleveland Equipment, we provide a variety of box taping and glue solutions to fit every business need. With multiple models in stock and ready to ship, we help businesses find the right solution at the right price—ensuring they can scale at a pace they can afford.

Here are some of the machines we offer, with reviews from our customers:

“I bought my machine 3 months ago and it has worked so well for the company that I ended up buying 2 more. I recommend this case taper to anyone. I was also happy to know we could test our boxes before confirming this machine worked for us.” -Bernard

“We have been very pleased with the equipment we have purchased. Everything has held up well, and they have represented the best value dollar-to-dollar when compared to 3 other brands of tapers we have purchased over the past 20 years or so. As contract packagers we might not run them every day, but when we do use them for a project they can be run for months at a time. They are mechanically solid, easy to set up, easy to use, easy to maintain, and are basically trouble free.” -Tenco Assemblies

“We purchased several of these and our employees love them. Things are operating much more smoothly and efficiently.” -Precision Tool & Plastic

“We're buying a second CE-554TS due to growth in business and just realized the last one we bought was over five years ago and is still going strong.” -Renu Chem Inc.

“The CE-30 case sealer we bought was the best investment we made. We no longer have to tape by hand and it has made our jobs a lot easier.” -Adam

“We run over 1000 boxes through them every project. They get quite the workout and do just what we need them to. -Twin Cities Railing

Get started

For businesses that are tired of slow, inefficient manual packaging, a box tape machine is a game-changer. By integrating a case sealer machine into your packaging workflow, you can cut packing time in half, reduce labor costs, minimize waste, and scale production effortlessly.

We are dedicated to helping you find affordable, high-quality packaging solutions that make a real impact. Whether you're shipping a few dozen boxes per day or scaling up to full-scale production, we have a box sealer machine that fits your needs.

Request a quote and discover how our solutions can transform your business!