3 affordable packaging solutions for mom-and-pop shops

Running a small business comes with unique challenges, especially when it comes to packaging. Mom-and-pop shops and small businesses often operate with limited budgets and staff, making efficiency a top priority. However, manually packaging products can be time-consuming, costly, and prone to errors.

That’s where semi-automated packaging equipment comes in. These solutions help businesses speed up their operations, maintain consistency, and reduce labor costs—all while staying within budget. At Cleveland Equipment, we specialize in providing high-quality, cost-effective packaging solutions that allow small businesses to scale at their own pace without breaking the bank.

Here are some of the benefits of semi-automated packaging equipment and three affordable solutions that can help mom-and-pop shops streamline their packaging process.

The benefits of semi-automated packaging equipment

For small businesses, every dollar and every minute counts. Investing in semi-automated packaging equipment can provide a significant return on investment (ROI) by reducing manual labor, minimizing waste, and increasing output. Here are some key benefits:

1. Cost-effectiveness

Hiring additional staff to manually fill, seal, and label products can be expensive. Semi-automated equipment allows you to get more done with fewer employees, reducing labor costs while increasing efficiency. Over time, the savings on labor alone can more than pay for the equipment itself.

2. Consistency and quality control

Hand-filling and sealing products often lead to inconsistent results, which can hurt your brand’s reputation. Semi-automated packaging equipment ensures that every product is filled, sealed, and labeled with precision, maintaining a professional appearance and reducing customer complaints.

3. Scalability

As your business grows, your packaging needs will increase. Instead of struggling with manual processes, semi-automated machines allow you to scale production without sacrificing quality. Whether you’re expanding your product line or fulfilling larger orders, the right equipment ensures you can meet demand efficiently.

3 affordable semi-automated packaging solutions

If you’re looking for ways to optimize your packaging process without a major investment, consider these three affordable solutions:

1. Piston fillers: filling equipment for liquids and creams

Piston fillers are an excellent choice for small businesses that package liquids, creams, sauces, and other semi-viscous products. They offer precise filling capabilities, reducing product waste and ensuring uniform packaging.

How it works: Our SGP Series is designed for both liquids and creams, while the SGY Series is tailored for liquids only. These machines operate pneumatically, making them ideal for wet environments or locations without electrical hookups. The fill cycle is activated by a foot pedal, making operation easy and efficient. Piston fillers are also safe and dependable; they can easily handle chemicals and flammable materials.

For small businesses selling cosmetics, food products, or cleaning supplies, a piston filler can help improve accuracy and reduce messes, leading to faster packaging and less wasted product.

2. Sealers: secure your packaging

A strong, professional seal is crucial for product safety and freshness. We offer multiple sealing solutions, including:

Continuous band sealers

How it works: Continuous band sealers can operate vertically or horizontally based on your packaging needs. They also include features like gas purge, vacuum sealing, or built-in inkjet coding for lot numbers and expiration dates.

Impulse heat sealers

How it works: Impulse heat sealers provide airtight or watertight seals, ideal for sterilization or autoclaving. As one of the more economical bag sealing options, they work on a variety of materials, including polyethylene, polypropylene, Mylar, and more.

Induction sealers

How it works: Induction sealers provide a contactless sealing method for plastic and glass containers. They help preserve freshness and extend shelf life, ensuring the integrity and longevity of your product for as long as possible.

Pinch bag sealers

How it works: Pinch bag sealers are ideal for sealing multi-walled paper bags. With secure seals on paper bags weighing up to 110 lbs, they are commonly used for items like food products, dry chemicals, and fertilizers.

For businesses selling perishable goods, dry ingredients, or sensitive products, investing in a high-quality sealer ensures product integrity and customer satisfaction.

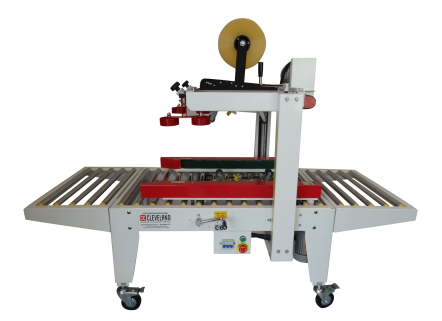

3. Case tapers: box taping and glue solutions for faster packing

Sealing boxes manually with tape dispensers is slow, inconsistent, and can lead to wasted tape. Case tapers, also known as box tapers or carton sealers, make sealing boxes effortless and efficient. Whether you’re shipping eCommerce orders or wholesale products, a case taper helps your business pack and ship faster with fewer errors.

How it works: A case taper saves time, reduces waste, and ensures secure packaging with consistent tape application. Our case tapers work with various box sizes and production levels, from small single-shift operations to 24/7 production lines.

Hear from our customers

As a leader in economically priced semi-automated packaging equipment, here are some of the ways our customers have benefited from our products.

“ work great with our CBD creams. I hear nothing but positive things from our team.” -Zillas CB Distro

“ is great. I find it easy to use. The ability to use it horizontally or vertically is a big plus for me. In addition, I like the fact that the embosser prints directly on seal lines without requiring ink.” -Thomas

“We're buying a due to growth in business and just realized the last one we bought was over five years ago and is still going strong.” -Renu Chem Inc.

Invest in semi-automated packaging solutions

Investing in semi-automated packaging equipment is one of the best ways for mom-and-pop shops to scale efficiently, reduce costs, and improve product consistency. Whether you need a piston filler for liquid products, a sealer for securing packaging, or a case taper for faster boxing, Cleveland Equipment has the perfect solution for your business needs.

Ready to boost your packaging efficiency? Request a quote and learn how our affordable solutions can help your business grow!