Labeling made easy: why your business needs a label applicator

In today’s market, efficiency is what can make you stand out among your competitors and ensure business success. For small and medium-sized businesses, optimizing processes can mean the difference between struggling with manual tasks and scaling profitably. One of the simplest yet most effective upgrades you can make is investing in a label applicator. If you’re still applying labels by hand, it’s time to explore a smarter, faster way to streamline your operations.

The importance of a label applicator

Labeling is a critical step in product packaging, influencing both branding and compliance. However, manual labeling can be time-consuming, inconsistent, and costly. With a bottle label applicator machine or an automatic label applicator machine, you can increase accuracy, efficiency, and professionalism while freeing up valuable staff time for higher-priority tasks.

A label applicator ensures that labels are applied uniformly every time, preventing misalignment, bubbling, or peeling that can make products look unprofessional. This is especially crucial for businesses in the food, beverage, and pharmaceutical industries, where product presentation and compliance with labeling regulations are essential. By upgrading to a label applicator, companies can ensure a consistent and polished look, boosting consumer trust.

Beyond aesthetics, a label applicator significantly reduces labeling errors that could lead to misbranding or misinformation. This is particularly beneficial for businesses with multiple product lines requiring different labels. Instead of risking human error in the manual application process, an automatic label applicator machine guarantees that the right label is placed on the right product every time, enhancing operational efficiency and reducing waste.

Benefits of automated labeling

1. Time savings

Applying labels manually is tedious and slow. A bottle labeling machine drastically reduces application time, allowing businesses to label hundreds or even thousands of products in the time it would take to label just a fraction manually. With a label applicator, your team can shift focus from repetitive tasks to growing the business.

For example, a small craft brewery that manually labels its bottles may struggle to keep up with increasing demand. Switching to an automatic label applicator machine enables them to triple their labeling speed, allowing them to distribute more products faster without hiring additional staff. This efficiency gain means they can allocate more resources toward product development and marketing.

Another example is a local cosmetics business selling various lotions and skincare products. Before investing in a bottle label applicator machine, teams can spend hours hand-labeling each container, leading to backlogs and shipping delays. With automated labeling, businesses reduce production time and meet customer orders faster, improving customer satisfaction and repeat business.

“Makes our workflow so much faster and efficient. ”

-Prairie Wolf Distillery

2. Enhanced precision and consistency

Misaligned or wrinkled labels can damage your brand’s credibility. With an automatic label applicator machine, every label is placed perfectly, ensuring a polished and professional look. Whether labeling bottles, boxes, or bags, you can count on consistent placement that enhances brand image and compliance with industry standards.

For example, a gourmet food company relies on precise labeling to showcase its premium products. A misplaced or crooked label could diminish the perceived value of its artisanal sauces or specialty oils. By using a bottle labeling machine, they can maintain high-quality presentation, reinforcing their brand’s reputation for excellence.

In industries such as pharmaceuticals, accurate labeling isn’t just about appearance—it’s about safety and regulatory compliance. A mislabeled medicine bottle could lead to serious health risks. Investing in a label applicator ensures every label is correctly placed, legible, and compliant with strict industry standards, reducing the risk of costly recalls or legal issues.

3. Cost efficiency

A label applicator reduces labor costs by eliminating manual work. Businesses investing in Cleveland Equipment’s semi-automated solutions often find they can allocate staff more effectively, leading to better productivity and profitability. Over time, the savings from reduced waste and fewer labeling errors add up significantly.

For example, a small coffee roastery can implement a flat label applicator and cut labor costs in half, reassigning employees to customer service and sales, which can result in overall improved business performance.

Without some form of automation, misapplied or torn labels can result in thousands of dollars in losses annually. With a label applicator, businesses drastically decrease errors, saving money and reducing their environmental footprint.

4. Scalability and growth

Expanding your business means increasing production capacity. Manual labeling becomes a bottleneck as demand grows. A bottle label applicator machine ensures that as orders increase, you can keep up without additional labor costs. By integrating an automatic label applicator machine, you position your business for long-term growth.

A bottle labeling machine allows businesses to scale production efficiently without hiring extra staff, maintaining profitability while expanding into new markets. This also helps smaller businesses pursue partnerships with larger retailers with confidence, knowing that they have the equipment to scale comfortably and accelerate their growth.

“We increased productivity from an average across all product lines from approximately 60 units per hour to approximately 320 units per hour.”

-ODW Logistics

5. Versatility across products

Whether you need to label bottles, cartons, or bags, there’s a label applicator that fits your needs. Our solutions accommodate various packaging formats, from flat label applicators for oddly shaped containers to bottle labeling machines for cylindrical products. With a versatile label applicator, businesses can maintain efficiency across different product lines.

“

has worked well so far – we use it to apply labels to 5 products of varying sizes and shapes, and we have been able to apply labels in a consistent and high quality.”

-Joy Organics

Examples of label applicators we offer

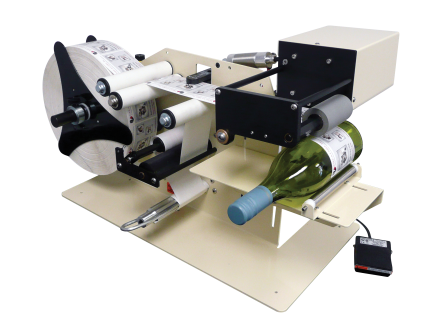

1. Desktop or inline bottle labeling solutions

If you need an affordable, high-quality bottle label applicator machine, we offer both semi-automatic desktop options and full integrated inline solutions. Our machines ensure precise labeling, whether you run a small craft business or a growing production line. These solutions will work seamlessly with your needs, creating an efficient production process.

“Have

on our first run without a single hiccup.”

-Horseshoe Bend Farm Wines

“We just

because these things are awesome. We use them for a lot of different sizes, from 4 ounce to gallon, and it works great with them all.”

-Fenix Group

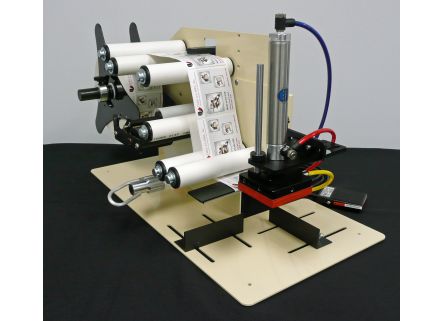

2. Flat label applicators

For businesses needing to label bags, square containers, or uniquely shaped items, our flat label applicators provide a perfect solution. There are also options available for labeling boxes as they move through taping, allowing for seamless integration into packaging lines. At the same time, by automating labeling, businesses can reduce manual labor.

“The amount of time we save using this [ ] is unbelievable.” -Cresco Labs

“[ ] has taken a big weight off our shoulders!” -Semolina Artisanal Pasta

Scale smarter and faster with Cleveland Equipment

At Cleveland Equipment, we provide affordable semi-automated packaging solutions, including piston fillers, bottle filling equipment, and box machines. We support small and medium businesses with financing options and a commitment to customer success.

Ready to transform your labeling process? Request a quote today and discover how our automatic label applicator machines can support your business!