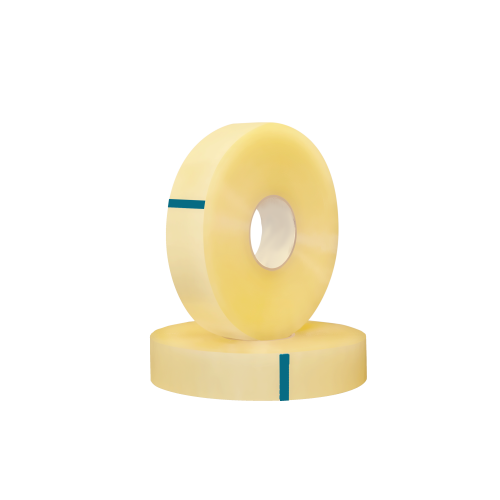

Max-Tac Acrylic Machine Tape 1.8mil 2" Case of 6 Rolls

- Buy 24 for $108.18 each and save 8%

- Buy 48 for $93.18 each and save 21%

Polypropylene tape water based acrylic adhesive

- Acrylic 2” x 1,000 yards 1.8 mil

- (6 Rolls / Case)

- Film: Biaxially Oriented Polypropylene

- Total Thickness: 1.8mils (nominal)

- Adhesive: Emulsion Acrylic

- Color(s): Clear

- Tensile Strength (lbs/in): 22 PSTC-131* (ASTM D3759**)

- Elongation (% at break): 140 PSTC-131 (ASTM D3759)

- 180° Peel Adhesion (oz/in): 22 PSTC-101 (ASTM D3759***)

- Persistance to UV Lighting: Excellent

- Application Temperature 32° to 140° F

- Operating Temperature -10° to 200° F – normal range

Use for bundling and sealing light to medium weight cartons in a wide range of temperatures where STA’s uniquely formulated age-resistant/non-yelling, fiber pulling acrylic adhesive is required.

Other Standards and Specifications

Conforms to FDA SPECS: 21 CFR 175.105 and CFR177.1520 for indirect food contact, (Clear tape only). Complies with environmental considerations of ASTM D 1974-14.

The conditions at which the tape is unwound and applied to the substrate. Under normal conditions the tape should unwind and adhere to the substrate properly, and perform as normally expected. The tape should be used within 1 year of the date of shipment.Application & Operating Conditions

Notes: *Shear is the tape’s ability to resist the sliding of two substrates relative to each other’s planes of contact. (to hold flaps down). The information listed above has been obtained from controlled laboratory tests and is reliable, but should not be used for the purpose of writing specifications. It is offered in good faith, but without guarantee, as conditions and methods of use of STA products are beyond STA’s control. It is recommended that the prospective user determine their suitability before adapting them on a commercial scale.

*Pressure Tape Council

***ASTM Standard D3330, “Standard Test Method for Peel Adhesion of Pressure Sensitive Tapes”

**ASTM Standard D3759, “Standard Test Method for Tensile Strength and Elongation of Pressure Sensitive Tapes”

ASTM International, West Conshohocken, PA. www.astm.org

| Film Type | Biaxially Oriented Polypropylene |

|---|---|

| Film Thickness | 1.8mils (nominal) |

| Adhesive | Emulsion Acrylic |

| Tensil | 22 lbs/in |

| Elongation | 140 (% at break) |

| Application Temperature | 32° to 140° F |

| Operating Temperature | -10° to 200° F – normal range |