Search results for: 'knowledge base labeling machines 77'

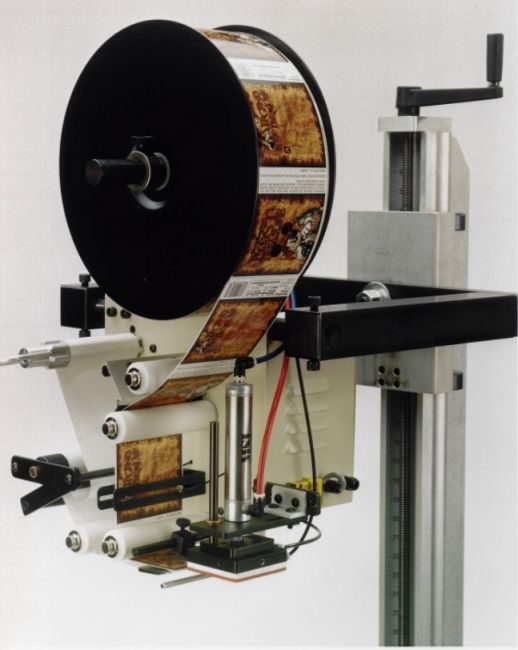

-

- Minimum Label Size: 1/2" x 1/2"

- Maximum Label Size: 5" x 15"

- Maximum Roll Diameter: 12"

- Core Size: 1" or 3"

- Shipping weight: 45 pounds

- Electrical Requirements: 115VAC. 60HZ.,

- 500" Per Minute

$5,798.00 -

- MADE IN USA

- 3 Year Warranty!

- Dispense labels 3/8" to 4.5" widths

- Butt cut, or die cut compatible!

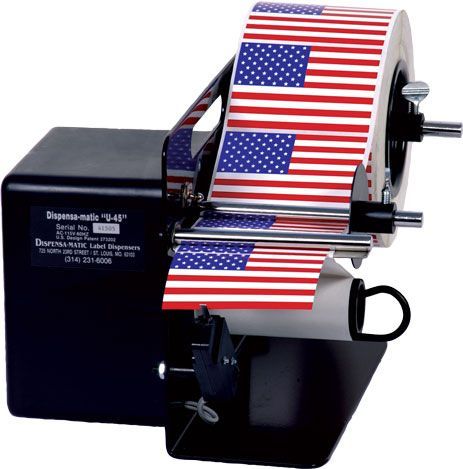

Available with Photoelectric IR Sensor or Microswitch!Dispensa-Matic U-45 Label Dispenser: Is a heavy-duty semi-automatic electric label dispenser for labels from 3/8"-4.5" widths x 3/8" to any length. This label dispenser advances at over 4" per second standard (Faster than so called High-Speed machines from competitors), and OVER 10" PER SECOND with our High-speed version!

$695.00 -

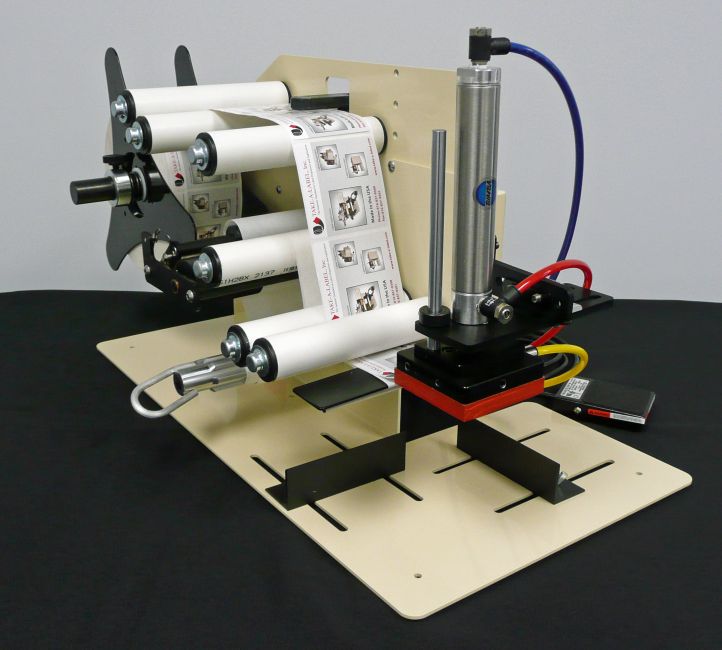

- Minimum Label Size: 1/2" x 1/2"

- Maximum Label Size: 5" x 5"

- Maximum Roll Diameter: 12"

- Core Size: 1" or 3"

- Shipping Weight: 45 pounds

- Air Requirements: 60PSI

- Electrical Requirements: 115VAC. 60HZ.

$6,850.00 -

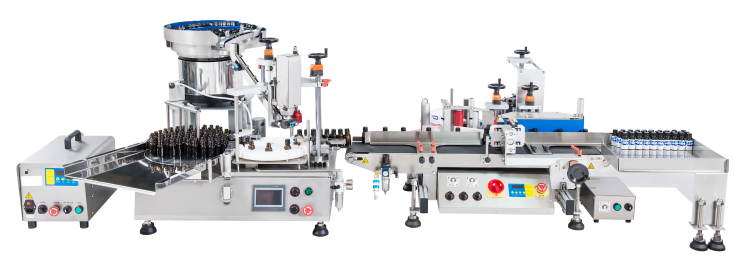

- Labeling speed: 20~60 pcs/ min

(depends on container and label size) - Bottle size: Diameter .63" (16mm) - 3.54" (90mm)

- Height 1.18" (30mm) - 6.29" (160 mm)

- Label size: Width:.39" (10mm) ~ 3.93" (100mm)

- Length: .78" (20mm) ~ 11.81" (300mm)

- Label reel: Inner diameter 2.95" (75mm)

- Outer Diameter 11.81" (300mm)

- Accuracy: ± 1mm

- Voltage : 110V

- Machine size: 47.25"L x 32.65"W x 20.86"H

$9,675.00 - Labeling speed: 20~60 pcs/ min

-

Heavy-Duty Semi-Automatic Electric Label Dispenser

Ideal for Front Labeling Only- Bottle Diameter: 1/2" - 6" Diameter

- Bottle Height: 2" - 15" Length

- Label Core: 3" Diameter Core

- Max Roll Size: 9" Diameter Roll

- Optional Upgrade: 15" Diameter Roll

- MADE IN USA

- 3 Year Warranty!

$2,195.00 -

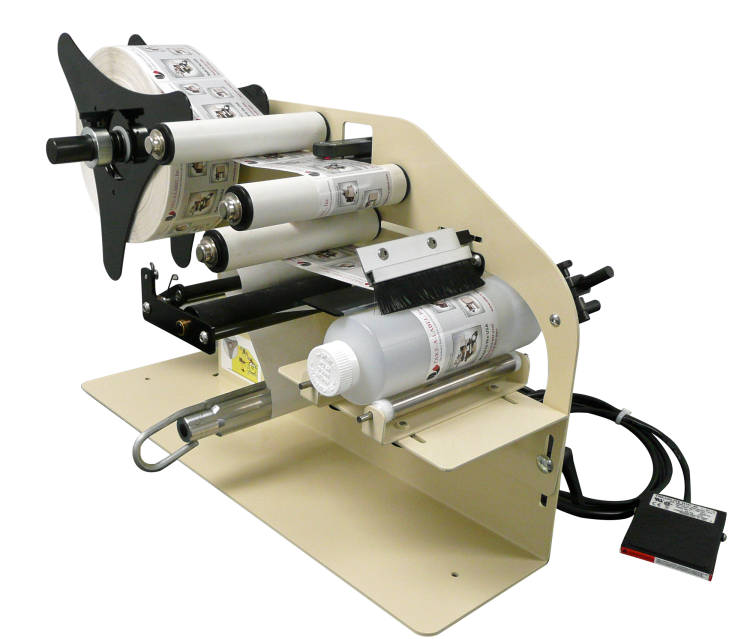

Heavy-Duty Semi-Automatic Electric Label Dispenser

Ideal for Front Labeling Only- Bottle Diameter: 1/2" - 6" Diameter

- Bottle Height: 2" - 9" Length

- Label Core: 3" Diameter Core

- Max Roll Size: 9" Diameter Roll

- Optional Upgrade: 15" Diameter Roll

- MADE IN USA

- 3 Year Warranty!

$1,995.00 -

- Labeling speed: 20~60 pcs/ min

(depends on containers and labels size) - Bottle size: Diameter .63" (16mm) - 3.54" (90mm)

- Height 1.18" (30mm) - 6.29" (160 mm)

- Label size: Width:.39" (10mm) ~ 3.93" (100mm)

- Length: .78" (20mm) ~ 11.81" (300mm)

- Label reel: Inner diameter 2.95" (75mm)

- Outer Diameter 11.81" (300mm)

- Accuracy: ± 1mm

- Voltage : 110V

- Machine size: 65"L x 36"W x 24"H

$11,500.00 - Labeling speed: 20~60 pcs/ min

-

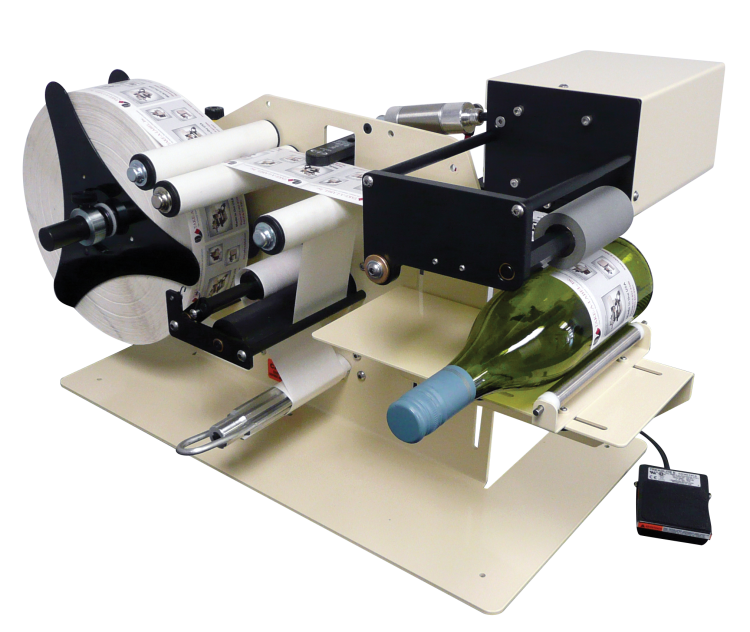

Heavy-Duty Semi-Automatic Electric Label Dispenser

Ideal for Front & Back Labeling- Bottle Diameter: 1/2" - 6" Diameter

- Bottle Height: 2" - 15" Length

- Label Core: 3" Diameter Core

- Max Roll Size: 9" Diameter Roll

- Optional Upgrade: 15" Diameter Roll

- MADE IN USA

- 3 Year Warranty!

$2,545.00 -

Heavy-Duty Semi-Automatic Electric Label Dispenser

Ideal for Front & Back Labeling- Bottle Diameter: 1/2" - 6" Diameter

- Bottle Height: 2" - 9" Length

- Label Core: 3" Diameter Core

- Max Roll Size: 9" Diameter Roll

- Optional Upgrade: 15" Diameter Roll

- MADE IN USA

- 3 Year Warranty!

$2,345.00 -

L-bar sealers use center fold film to protect your products and give them an attractive, professional look. Cleveland Equipment's CEFQL380 L-Bar Sealer is easy to use and to maintain and is an excellent L-sealer for many types of products. Weighing 77 pounds, this machine can handle maximum sealing dimensions of 19.65" x 13.75". It's small enough to set up on a tabletop or desk.$439.00

-

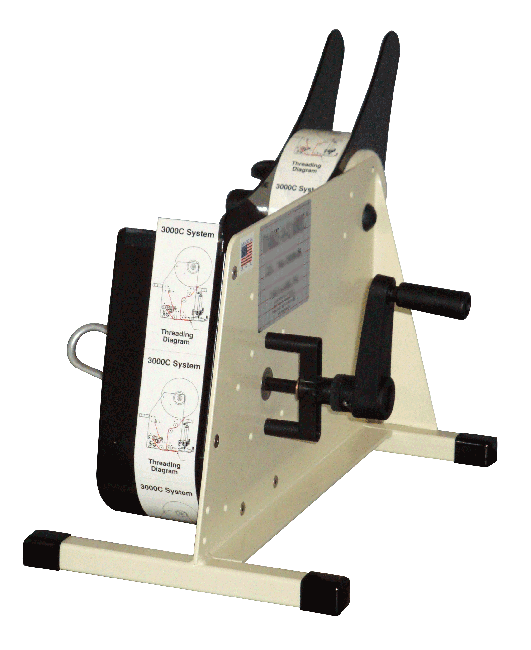

Label bags, envelopes, CD/DVD cases

1200 Pcs. per hour!

fast and accurately- Label objects to 1/4" width.

- Able to handle most plastic bags without difficulty.

- Labels over 1200 pcs per hour with average dexterity.

- Photodetector activated, will work on all kinds of labels.

$2,895.00 -

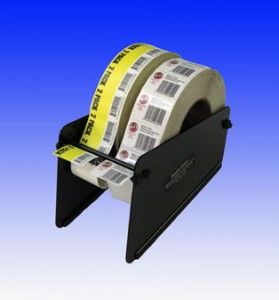

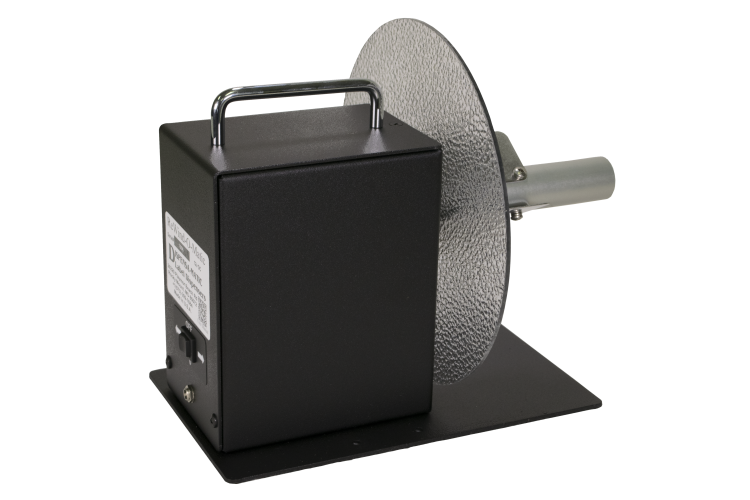

- Full Scrap Rewind

- Label Roll Diameter up to 12”

- Durable All Steel Frame with Powder Coat Finish

- Dispenses Die-cut or Butt-cut Labels

- Accommodates Multiple Labels on a Common Liner

- Shipping Weight: 13 Lbs.

- Maximum Web Width: 2.5"

- Maximum Roll Diameter: 12"

- Core Size: 1" or 3”

$290.00 -

- Scrap rewind for quick start and removal of waste liner

- Full scrap rewind feature

- Durable all steel frame with powder coat finish

- Footswitch activated

- Accuracy +/- 1/16”

- Minimum Label Size: 1/2 x 1/2”

- Maximum Label Size: 5” x 5”

- Maximum Roll Diameter: 12”

- Core Size Diameter: 1” or 3”

- *All clear labels must be tested

$4,698.00 -

with Optional Inject Printer

- *Works with the largest range of bottles

(1/4” to 6.5” Diameter) - Solid state electronics

- Scrap rewind for quick start and removal of waste liner

- Photo cell label sensor

- Durable all steel frame with powder coat finish

- Footswitch activated

- Product Size: 1/4” to 6.5” Diameter

- Minimum Label Size: 1/2 x 1/2”

- Maximum Label Width: 5”

- Maximum Roll Diameter: 12”

- Core Size Diameter: 1” or 3”

- *All clear labels must be tested

$4,798.00 - *Works with the largest range of bottles

-

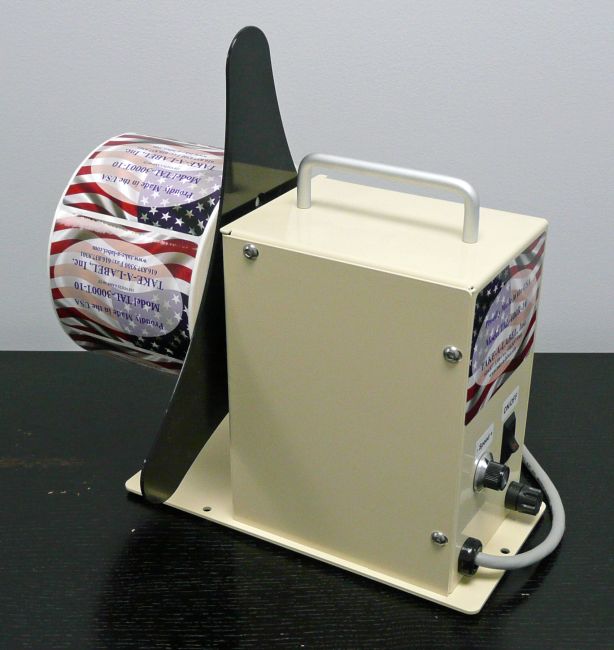

- All Steel Frame Construction.

- Standard Photo Cell

- Open vertical peel edge will not trap labels and allows multiple labels on common liner to be dispensed.

- Heavy duty motor with built in overload protection.

- Shipping weight: 26 lbs.

- Max label width: 7.5"

- Max roll diameter: 12"

- Core size: 3"

$859.00 -

- Label Roll Diameter up to 10”

- Inside Roll Guide

- Durable All Steel Frame with Powder Coat Finish

- 3” Core

- Adjustable Speed Dial

- 4.5” Web Capacity

- Web Speed up to 12 IPS

$565.00 -

- All Steel Frame Construction.

- Open vertical peel edge will not trap labels

- Allows multiple labels on common liner to be dispensed.

- Heavy duty motor with built in overload protection.

- Shipping weight: 24 lbs.

- Max label width: 4.5"

- Max roll diameter: 12"

- Core size: 1" or 3"

$698.00 -

Dispensers for labels from 3/8″-4″ widths on Simple Simon 4″ and from 3/8″ – 6 3/4″ widths to any length$85.00

-

Dispensers for labels from 3/8″-4″ widths on Simple Simon 4″ and from 3/8″ – 6 3/4″ widths to any length$95.00

-

- All Steel Frame Construction.

- Open vertical peel edge will not trap labels and allows multiple labels on common liner to be dispensed.

- Heavy duty motor with built in overload protection.

- Shipping weight: 22 lbs.

- Max label width: 2.5"

- Max roll diameter: 12"

- Core size: 1" or 3"

$613.00 -

- No Tools Required

- Made in the USA

- Fully adjustable unwind tension

- Waste rewind spindle to collect backing paper

- Durable all steel frame with powder coat finish

- Product Size: 1” to 5” Diameter*

- Minimum Label Size: 1” x 1”

- Maximum Label Width: 5”

- Maximum Roll Diameter: 12”

- Core Size Diameter: 1” or 3”

- *All clear labels must be tested

$2,165.00 -

Liquid Filling Line with Gear Filler Machine or Peristaltic Pump Machine

CFL200 Liquid Filling Line Machine: At a Glance

Quickly and confidently set up a bottle filling line in a small space. Start a more efficient production run for your business with this compact liquid packaging line machine. Fill up to one bottle per second with assistance from automated processes. Compatible with a wide range of liquid products.

- Volume range: 5 - 240ml per cycle

- Filling speed: up to 60 bottles /min depending on fill volume

- Filling accuracy: +/-1%

$38,995.00 -

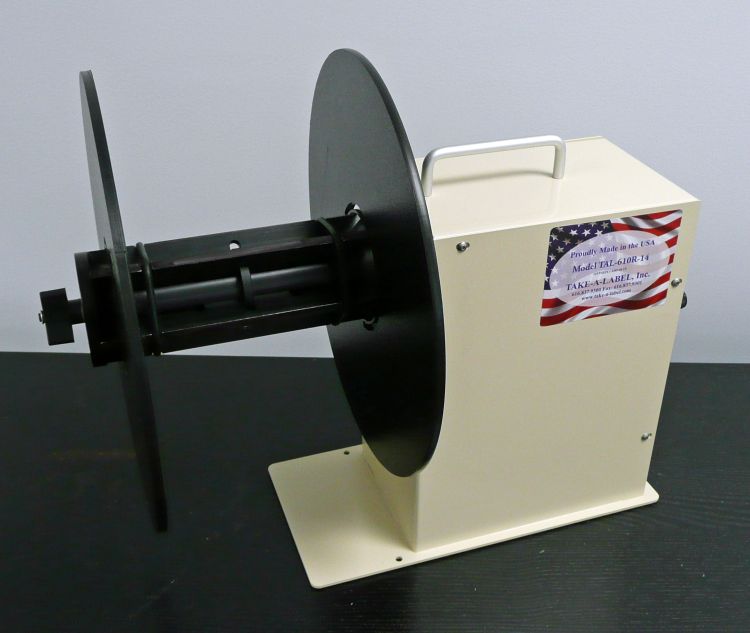

- 3” Expanding Mandrel

- Inside and Outside Roll Guides

- Durable All Steel Frame with Powder Coat Finish

- Made in the USA

- 12" Max Roll Diameter

- 6.5" Max Web Width

- Web Speed up to 25 IPS

$1,130.00 -

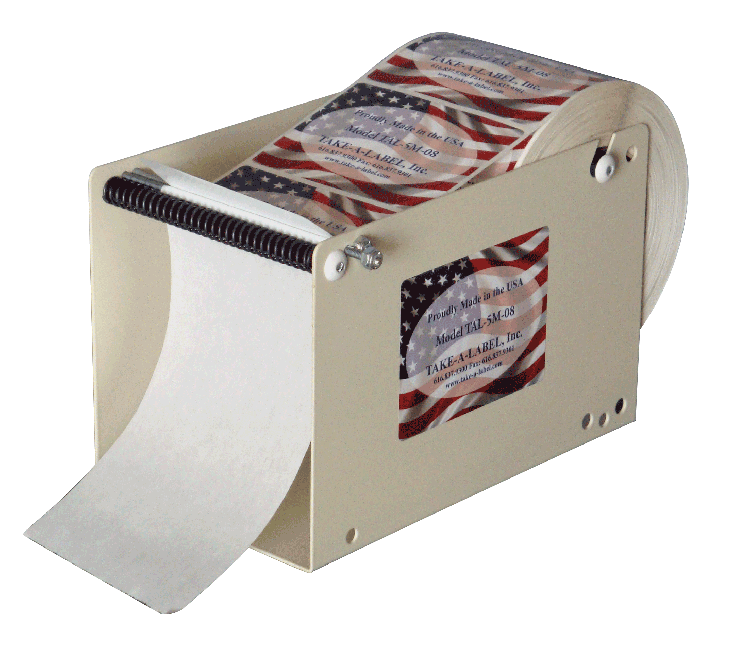

- Maximum Web Width: 5"

- Maximum Roll Diameter: 8"

- Core Size: 1" or 3” Diameter

$59.00 -

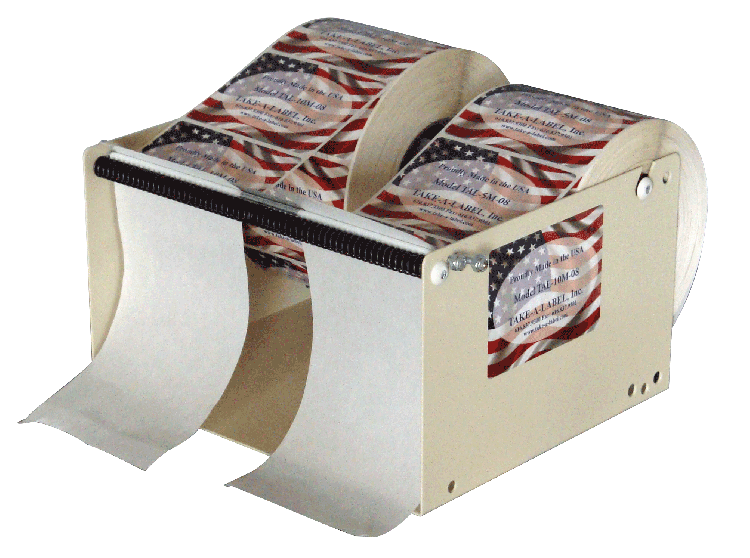

- Maximum Web Width: 10”

- Maximum Roll Diameter: 8”

- Core Size: 1" or 3” Diameter

$69.00 -

- Tunnel size (mm) 1000x150x150

- Tunnel size (in) 39.4" x 6" x 6"

- Max.Packing size mm 105 x 350H

- Max.Packing size (in) 4.14" x 13.78"

- Conveyor motor AC90W/220V

- Conveyor speed 0-10m/min

- Max.loading 15KGS

- Shrink film POF,PVC,PP

- Voltage 220V /60HZ, Single Phase, 7KW

- 36 Amps

- Dimension (mm) 1500x350x1500

- Dimension (in) 59"x13.78"x59"

- Dimension from floor to conveyor (adjustable) 23"-28"

$3,488.00 -

In Stock

- Power Supply:110V

- Min Carton size: 9.84 " L x 5.90" W x 3.94” H (250 x 150 x 100 mm)

- Max Carton Size: 21.65 " L x 15.75" W x 15.75” H (550 x 400 x 400 mm)

- Working speed: 12ctns/min

- Machine size: 79"L x 74"W x 57"H

- Machine weight: 990 lbs

$19,690.00 -

- Tunnel size 800x200x400 mm (31.49" x 7.87" x 15.75")

- Max.Packing size 160 x 350H mm (6.29" x 13.78")

- Conveyor motor DC50W/220V

- Conveyor speed 0-10m/min

- Max.loading 15KGS (33 lb)

- Shrink film POF,PVC,PP

- Voltage 220V /60HZ, Single Phase, 9KW

- 36 Amps

- Dimension 1500x400x1520 mm (59" x 15.75" x 60")

- Dimension from floor to conveyor (adjustable) 23"-28"

$3,488.00 -

- Tunnel size 800x200x400 mm (31.49" x 7.87" x 15.75")

- Max.Packing size 160 x 350H mm (6.29" x 13.78")

- Conveyor motor DC50W/220V

- Conveyor speed 0-10m/min

- Max.loading 15KGS (33 lb)

- Shrink film POF,PVC,PP

- Voltage 220V /60HZ, Single Phase, 9KW

- 36 Amps

- Dimension 1500x400x1520 mm (59" x 15.75" x 60")

- Dimension from floor to conveyor (adjustable) 23"-28"

$3,488.00 -

-

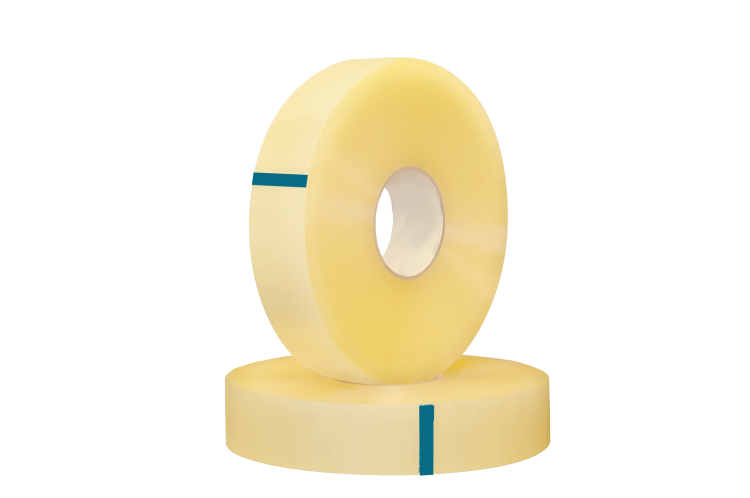

Polypropylene tape water based acrylic adhesive

- Acrylic 2” x 1,000 yards 1.8 mil

- (6 Rolls / Case)

- Film: Biaxially Oriented Polypropylene

- Total Thickness: 1.8mils (nominal)

- Adhesive: Emulsion Acrylic

- Color(s): Clear

- Tensile Strength (lbs/in): 22 PSTC-131* (ASTM D3759**)

- Elongation (% at break): 140 PSTC-131 (ASTM D3759)

- 180° Peel Adhesion (oz/in): 22 PSTC-101 (ASTM D3759***)

- Persistance to UV Lighting: Excellent

- Application Temperature 32° to 140° F

- Operating Temperature -10° to 200° F – normal range

$118.14 As low as $93.18 -

Polypropylene tape water based acrylic adhesive

- Acrylic 3” x 1,000 yards 1.8 mil

- (4 Rolls / Case)

- Film: Biaxially Oriented Polypropylene

- Total Thickness: 1.8mils (nominal)

- Adhesive: Emulsion Acrylic

- Color(s): Clear

- Tensile Strength (lbs/in): 22 PSTC-131* (ASTM D3759**)

- Elongation (% at break): 140 PSTC-131 (ASTM D3759)

- 180° Peel Adhesion (oz/in): 22 PSTC-101 (ASTM D3759***)

- Persistance to UV Lighting: Excellent

- Application Temperature 32° to 140° F

- Operating Temperature -10° to 200° F – normal range

$118.16 As low as $93.20 -

Polypropylene tape water based acrylic adhesive

- Acrylic 2” x 1,000 yards 2.0 mil

- (6 Rolls / Case)

- Film: Biaxially Oriented Polypropylene (BOPP)

- Total Thickness: 2.0 mils (nominal)

- Adhesive: Emulsion Acrylic

- Color: Clear

- Tensile Strength (lbs/in): 24 PSTC-131* (ASTM D3759**)

- Elongation (% at break): 140 PSTC-131 (ASTM D3759)

- 180° Peel Adhesion (oz/in): 24 PSTC-101 (ASTM D3759***)

- Resistance to UV Lighting: Excellent

- Application Temperature: 32° to 140° F

- Operating Temperature: -10° to 200° F – normal range

$123.48 As low as $98.52 -

Polypropylene tape water based acrylic adhesive

- Acrylic 3” x 1,000 yards 2.0 mil

- (4 Rolls / Case)

- Film: Biaxially Oriented Polypropylene (BOPP)

- Total Thickness: 2.0 mils (nominal)

- Adhesive: Emulsion Acrylic

- Color: Clear

- Tensile Strength (lbs/in): 24 PSTC-131* (ASTM D3759**)

- Elongation (% at break): 140 PSTC-131 (ASTM D3759)

- 180° Peel Adhesion (oz/in): 24 PSTC-101 (ASTM D3759***)

- Resistance to UV Lighting: Excellent

- Application Temperature: 32° to 140° F

- Operating Temperature: -10° to 200° F – normal range

$123.52 As low as $98.52 -

The CE-8 Manual Coding Machine is a hot code printer ideal for imprinting date codes, lot numbers, expiration dates, and other letters/numbers into plastic and paper bags.$175.00

-

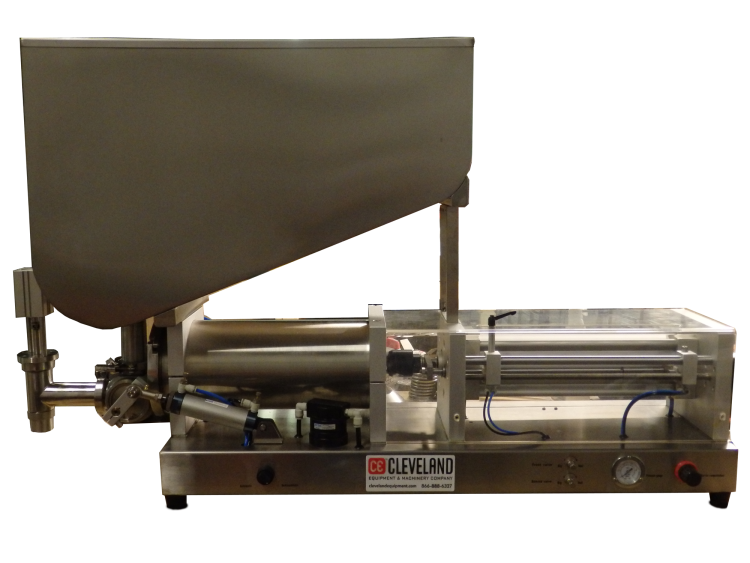

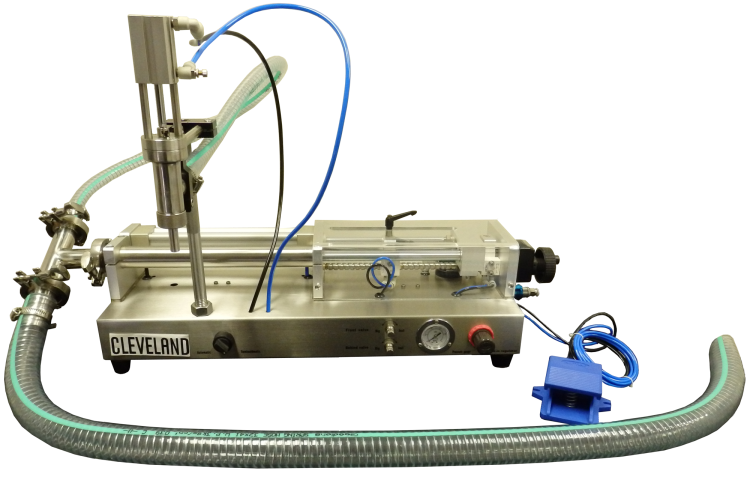

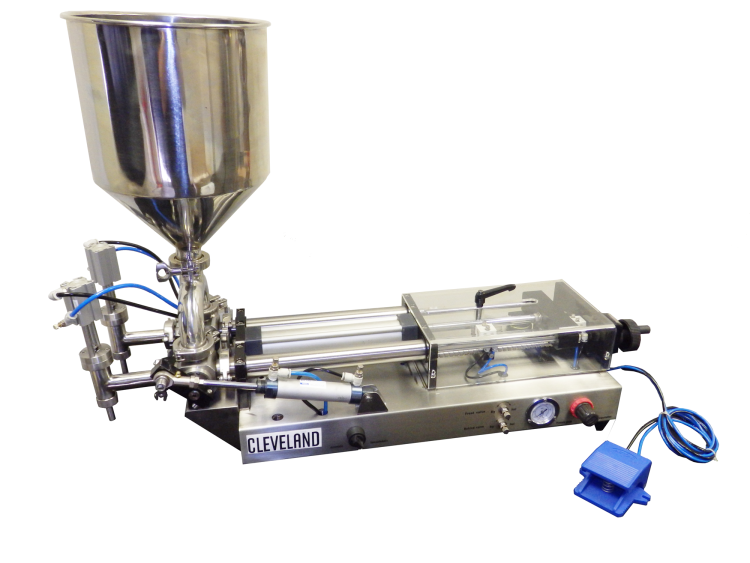

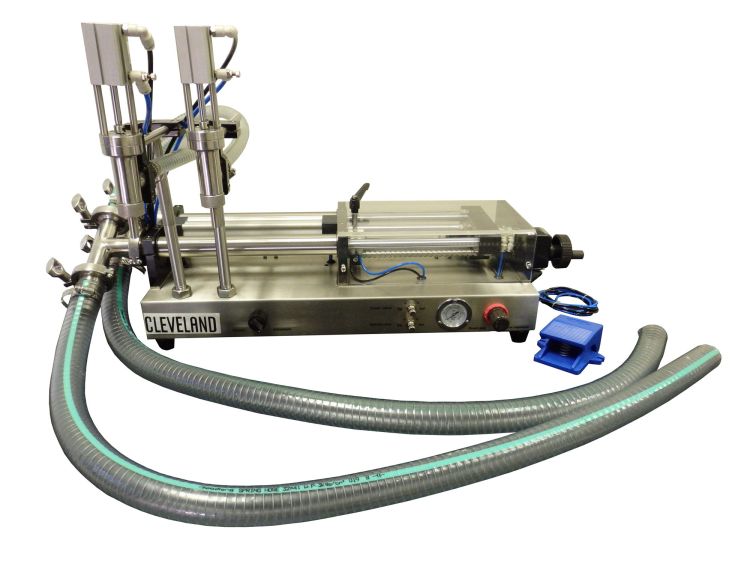

0.34 - 2.0 oz / 10ml - 60ml

Our piston filling machines are the ideal jar filling equipment for liquid fill and paste filling applications.As low as $4,189.00 -

BOX CODE PRINTER

Mount on any of our carton sealers!

- CoPilot uses proven Xaar piezo technology resulting in razor-sharp print

- Print up to .7″ of hi-resolution characters, bar codes, and logos at 185 dpi

- CoPilot’s 4.3″ full color touchscreen

- Compatible with Squid Ink’s easy-to-use Orion™ message software

** Ink not included with printer purchase

The CoPilot Hi-Resolution Printing System utilizes oil-based inks for printing on a wide range of porous substrates.

Not compatible with solvent-based inks / non-porous substrates.*

** Ink not included with printer purchase.

** Contact a sales rep to customize for your application.$2,695.00 -

When it comes to convenience, you can’t do much better than this hand-held electric capping machine. It is easy to carry, and is mainly used for easy screwing (tightening) and unscrewing (loosening) of the cap.

Since the design has an adjustable clutch, it is suitable for all kinds of strength bottle capping work. Applying to bottle cap ranges of 10-50 mm, and single production capacities of up to 30-90 bottles / min, this convenient device is also highly effective.

Here are a few more details pertaining to this bottle capping machine, as well as some reviews to consider:

Capping diameter : 10-50mmProduction capacity: 15-20 bottles / minute (depending on proficiency)Bottle Height: not limitedTorque :5-25kgf.cm$295.00 -

Optically sensing and includes all options! Bottle and Cylindrical Label Applicator with Optical Sensor for .5" to 8" Diameters!$3,395.00

-

Auto-Matic Bottle Detector option allows you to just insert your bottle and the labeler automatically activates.$150.00

-

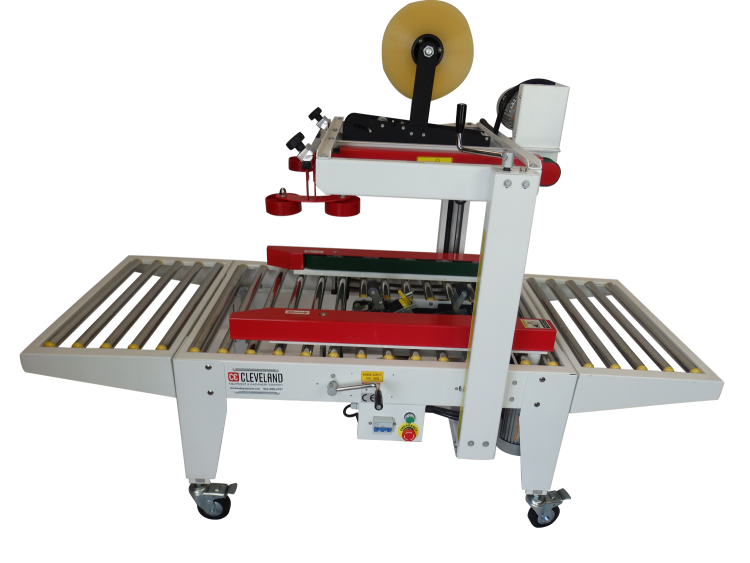

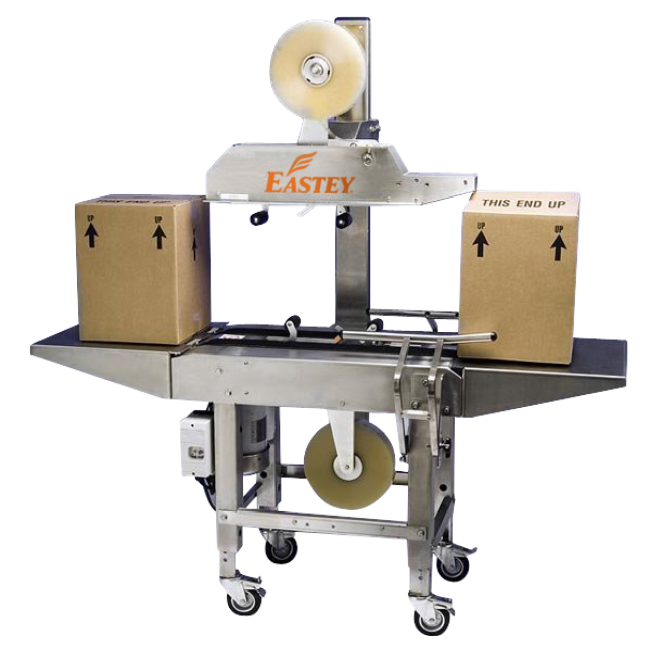

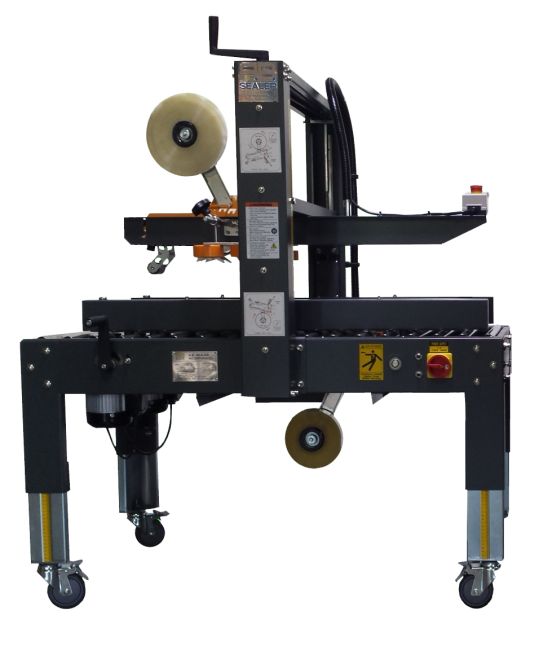

Top & Bottom Case Sealer

Our industrial-grade semi-automatic box sealers are designed for both small- and large-scale businesses. Well-equipped with powerful, reliable motors and belt systems that are truly made to last, these industrial carton sealers provide clean and uniform seals on boxes small and large. Three heavy-duty motors allow these machines to run safer for longer, while intuitive, easy-to-use functions mean simple operation for your whole staff. Cleveland Equipment provides financing on carton sealers and can ship them to you in as little as 24 hours.

- Drive: Top and Side Belts

- Minimum Box Size: 5.9"(L) x 4.75"(W) x 6.5"(H)

- Maximum Box Size: 27"(W) x 27"(H)

- (3) Heavy Duty 200 Watt Motors ( Competitors use 120 watt motors )

- Belt Speed: 59'/ minute (18m/min)

- 2" Tape Heads (3" Tape Heads Optional)

- Includes 16" Wide Infeed/Outfeed Tables ( Included )

- Power: 110V 60HZ

- Breaker Switch ( Not found on competitors machines )

- Emergency Switch

As low as $4,077.00 -

- Industrial Capsule Counting Bottle Filler

- Bottle: Diameter: 1.89" - 3.93" (48-100mm) / Height: 4.56" (116mm)

- Capsule size: Diameter > 6mm, H > 3mm

- Tablet size: 2~30mm

- Accuracy: ± 1 tablet

- Counting speed: 600~1000 pcs/min

- Voltage : 110V

- Dimension: (L) 29.5" x (W) 21.65" (H) 29.5"

$8,795.00 -

- Conveyor speed 0-10m/min

- Max.packaging size 3.15 x 11.4 inches (80x290mm)

- Tunnel size 39.37 x 4 x 12.5 Inches (1000x100x320 mm)

- Max.loading 33lbs (15kg)

- Shrink film POF,PVC,PP

$6,750.00 -

Economical Unit for Medium and Small Production Filling

- 7.5 Gallon Hopper

- Fill amount 4oz to 2.5 gal

- Min bottle height 4 in Max 15 inches

- Min bottle opening ½ inch

- Handles from 3 to 30 containers per minute*

- Accepts Free-flowing and low viscosity liquids

- Stainless Steel tank

- Stainless Steel Spouts

- Painted Stand (Stainless Steel Optional)

- Capable of 20+ quarts of water per minute

- Capable of 10+ quarts of syrup per minute

- Capable of 10+ gallons of water per minute

- *Test results based on standard 5 spout machine

$4,695.00 -

Universal Label Re-Winder with 3" core plates and inner flange. For rolls up to 6" width.$550.00

-

- Up To 15 Cases per Minute!

- Minimum Case Length = 6"

- Minimum Case Width = 4.5"

- Minimum Case Height = 4"

- Maximum Case Width = 14"

- Maximum KD Case (L + W) = 29"

- Maximum Case Height = 30"*

- FOOTPRINT: 82.5" L x 67" W x 80" H

- Stainless Steel Upgrade Available!

$32,990.00 -

- Up To 12 Cases per Minute!

- Minimum Case Width = 8"

- Maximum Case Width = 22"

- Minimum Case Height = 4"

- Maximum Case Height = 37"*

- Maximum KD Case (L + W) = 44"

- FOOTPRINT: 105" L x 91.75" W x 88.5" H

- Stainless Steel Upgrade Available!

$40,975.00 -

(Min) 1ml - (Max)1.4 Liters

- Type of Machine: Bottle Filler / Gear Filler

- Construction: 304 Stainless Steel Food Grade Standard

- Seals: Buna Food Grade Standard

- Tubing: 5/8 inc OD

- Valve: 3/8"

- Spring: Stainless Food Grade Standard

- Output: (Min) 1ml - (Max)1.4 Liters

$2,871.00 -

Speed: Up to 300 Cases/Hour (65 fpm belt speed)

Case Length: 6" minimum – 30" maximum

Case Width: 4" minimum – 27" maximum

Case Height: 6" minimum – 20" maximum$24,500.00 -

(Min) 5ml - (Max)10 Liters

- Type of Machine: Bottle Filler / Gear Filler

- Construction: 304 Stainless Steel Food Grade Standard

- Seals: Buna Food Grade Standard

- Tubing: 5/8 inc OD

- Valve: 3/8"

- Spring: Stainless Food Grade Standard

- (Min) 5ml - (Max)10 Liters Per Head Each Nozzle Fills quantity of 35 , 1-Oz bottles of water in 60 seconds

$4,451.00 -

- Top and bottom belt drives

- Suitable for all general boxes. To seal the box’s top and bottom edges, four edges sealed continuously

- PLC controlled

- Adjusted manually for box width by crank handle

- Infeed push-carton conveyor Box height adjustment is motor-driven (up/down movement)

- Locking casters standard

- Easy operation and maintenance

- Built for 24/7 Operation

- Adjustable leg supports

$24,900.00 -

- Sealing Speed: 0-16 m/min

- Sealing Width: 8-10 mm

- Sealing Temperature: 0-300° C

- Film Thickness: ≤.08mm

- Max Bag Weight: ≤ 1kg

- Max Conveyor Weight: ≤ 3kg

- Horizontal Only

$2,745.00 -

0.34 - 2.0 oz / 10ml - 60ml

$4,189.00 -

18.5 - 169.0 oz / 550ml - 5000ml

$6,655.00 -

- Up To 15 Cases per Minute!

- Minimum Case Length = 6"

- Minimum Case Width = 4.5"

- Minimum Case Height = 4"

- Maximum Case Width = 14"

- Maximum KD Case (L + W) = 28"

- Maximum Case Height = 30"*

- FOOTPRINT: 109" L x 68" W x 77.5" H

- Stainless Steel Upgrade Available!

Hot Glue Sealing System

$52,280.00 -

The BB-2 Bottom Belt Stainless Steel Industrial Case Taper is a cost-effective top and bottom case taper designed for large run case sealing. The BB-2 utilizes pressure-sensitive tape and features self-centering side rails, a rugged bottom belt drive, and heavy-duty mast that easily adjusts to handle a variety of case sizes.

- Bottom Belt Drive

- wash-down NEMA 4

- Includes 1 pack table

- Minimum Box Size: 5"(L) x 6"(W) x 4"(H)

- Maximum Box Size: ∞"(L) x 21"(W) x 20.5"(H)

- Single drive motor

- Tape Speed: 30 cases/min

- Belt Speed: 60ft/min

- Power Supply 110 VAC, 60Hz, 6A

-

1.0 - 4.0 oz / 30ml - 120ml

$4,289.00 -

1.5 - 8.5 oz / 45ml - 250ml

$4,385.00 -

2.5 - 16.9 oz / 75ml - 500ml

$4,485.00 -

Case Length: 6" minimum — 20" maximum

Case Width: 6" minimum — 20" maximum Case

Height: 4.5" minimum — 20" maximum

Electrical: 1 1 OVAC-I PH-60Hz - 10 Amps

$6,995.00 -

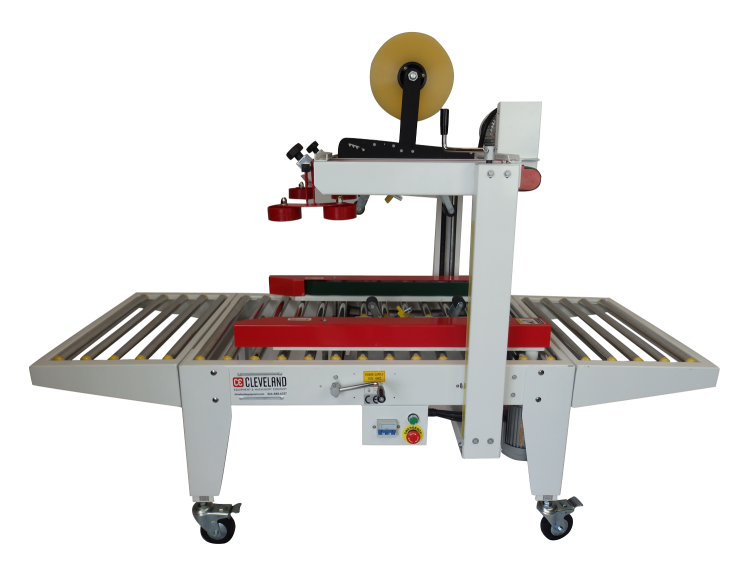

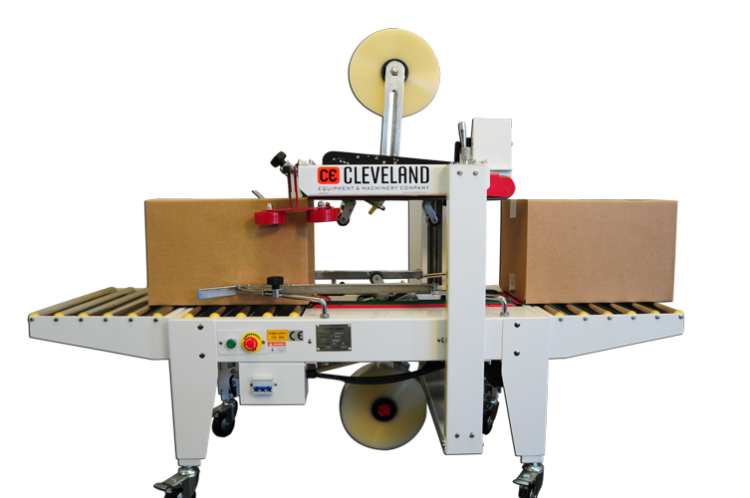

Top & Bottom Case Sealer

Cleveland Equipment semi-automatic box sealers are designed to help you save time and money. Adjustable belt systems allow you to tailor the machine to both small and large boxes for clean, uniform seals each and every time. Each carton sealer has a set of powerful, reliable 200 watt motors ( our competitors use under sized 120 watt motors ) and features user-oriented operations to make running it a breeze. Please make note of the breaker switch which is not offered by our competitors. In case of a power surge this will protect the electrical components. Our machines are well-suited for all levels in the packaging industry. We stock our machines so they are available to ship to you within 24 hours.

- Drive: Top and Side Belts

- Minimum Box Size: 5.9"(L) x 4.75"(W) 6.5"(H)

- Maximum Box Size: 19.6"(W) x 19.6"(H)

- (3) Heavy Duty 200 Watt Motors ( Competitors use 120 watt motors )

- Belt Speed: 59'/ minute (18m/min)

- 2" Tape Heads (3" Tape Heads Optional)

- 16" Wide Infeed/Outfeed Tables ( Included )

- Power: 110V 60HZ

- Breaker Switch ( Not found on competitors machines )

- Emergency Stop

As low as $2,895.00 -

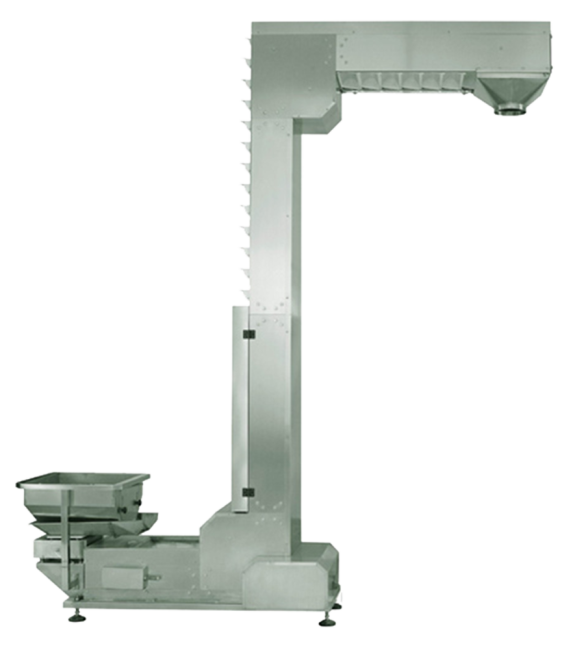

- Infeed Hopper Capacity: 100L

- Dispensing Height: 69"

- Bucket volume: 1.8L

- Bucket size: 16.5" L x 5.5" W x 2.76"H

- Dispersing Height 69"

- Lifting speed 2.5 - 5 cubic meter/hour

- Power 550w Voltage 220v

- Size 63"(Base)/110"(Overall) L x 34" W x 89" H (2790x860x2260mm)

- Specification The parts contacted with food are food grade plastic

- Requires Assembly*

$14,450.00 -

- Speed: Up to 700 Cases/Hour (65 fpm belt speed)

- Minimum Box Size: 6"(L) x 4.75"(W) x 4.5"(H)

- Maximum Box Size: 30" (L) x 20" (W) x 20" (H)

- Electrical: 110VAC--60Hz – 10 Amps

- Air: 1 SCFM @ 70 psi

- Dimensions: 75"L x 38"W x 63"H

- Weight: 650 lbs

$8,995.00 -

- Speed: Up to 720 Cases/Hour (65 fpm)

- Case Length: 6" minimum – no maximum

- Case Width: 4.75" minimum – 20" maximum

- Case Height: 6" minimum – 20" maximum

$7,900.00 -

- Bottle: Diameter: 1.89" - 3.93" (48-100mm) / Height: 4.56" (116mm)

- Capsule size: Diameter > 6mm, H > 3mm

- Tablet size: 2~30mm

- Accuracy: ± 1 tablet

- Counting speed: 600~1000 pcs/min

- Voltage : 110V, 50/60Hz

- Amperage: 2A

- Power: 100W

- Dimension: (L) 29.5" x (W) 21.65" (H) 29.5"

$8,795.00 -

Speed: Up to 2,400 Cases/Hour (65 fpm)

Case Length: 6" minimum – no maximum

Case Width: 7" minimum – 20" maximum

Case Height: 4.5" minimum – 20" maximum

Electrical: 110VAC-1PH-60Hz – 10 Amps

Air: None

Dimensions: 40"L x 31"W x 50-65"H

Weight: 300 lbs$4,850.00 -

*Designed for small boxes

Minimum box size 7 x 3.14 x 3.94

Maximum box size 10 x 7.87 x 7.87

Output is estimated at 12-15 boxes / min.$26,795.00 -

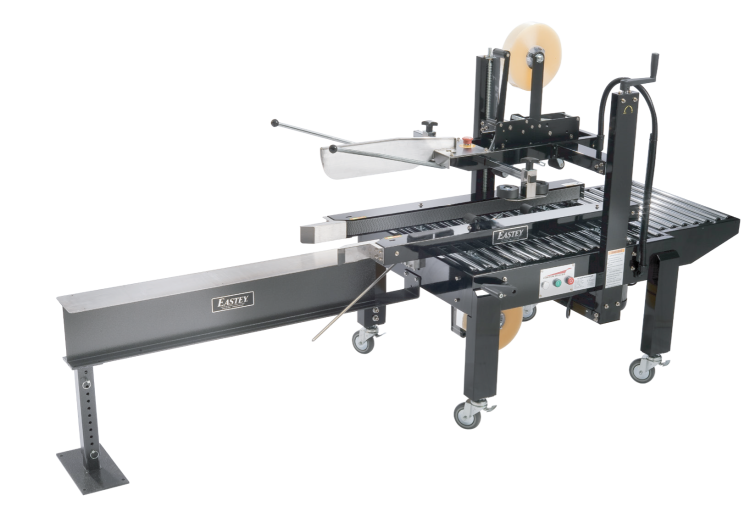

Eastey's SB-EX Random allows users to run a variety of case sizes without having to manually adjust for each box. The system's unique and simple design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum and providing fast and efficient alternatives to hand taping.

Machine Dimensions:- (L) 46in (1160mm)

- (W) 40.6in (1030mm)

- (H) 61in (1550Dimensions for SBEX Fully Auto

- (L) 46in (1160mm)

- (W) 40.6in (1030mm)

- (H) 61in (1550mmmm

- Top & Bottom Belt Drive

- Minimum Box Size: 5"(L) x 4.5"(W) x 4.5"(H)

* May be able to run smaller boxes with testing - Maximum Box Size: ∞"(L) x 23"(W) x 23"(H)

- Dual 1/4 HP drive motors

- Tape Speed: 30 cases/min

- Belt Speed: 75ft/min

- Power Supply 110 VAC, 60Hz, 6A

As low as $10,300.00 -

- Side Belt Drive

- Minimum Box Size: 5"(L) x 4.5"(W) x 4.5"(H)

* May be able to run smaller boxes with testing - Maximum Box Size: ∞"(L) x 19.5"(W) x 19.5"(H)

- Dual 1/4 HP motors

- Tape Speed: 30 cases/min

- Belt Speed: 75ft/min

- Power Supply 110 VAC, 60Hz, 6A

The SB-EX Case Taper system's unique and simple design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum and providing fast and efficient alternatives to hand taping.As low as $5,150.00 -

The SB-2HD’s side belts are great for light or heavyweight, narrow or small boxes. The system is ideal for void fill cases where the packaged product does not support the box. SB-2HD is designed to handle boxes that most other case tapers can’t. SB-2HD offers fast and easy case changes with adjustable side rails and flexibility for boxes 4.5” long and as narrow as 4” wide and as low as 2” tall.

- Side belt, top and bottom case sealer

- Belt Speed – 72 feet/per minute

- Tape Speed – 30 cases/per minute, depending on box size and operator efficiency

- No air required

- Minimum Box Size: 4.5” (L) x 4.0” (W) x 2.0” (H)

- Maximum Box Size: Infinite (L) x 20” (W) x 25.5” (H)

As low as $8,050.00 -

Top & Bottom Case Sealer

- Speed: Up to 2,400 Cases/Hour (65 fpm)

- Minimum Box Size: 6"(L) x 4.5"(W) x 3"(H)

- Maximum Box Size: ∞"(L) x 20"(W) x 38"(H)

- Electrical: 110VAC-1PH-60Hz – 10 Amps

- Air: None

- Casters are included in the standard unit.

- Dimensions: 51.5"L x 38"W x 56"H

$5,159.00 -

Top & Bottom Case Sealer

- Speed: Up to 2,400 Cases/Hour (65 fpm)

- Minimum Box Size: 6"(L) x 4.5"(W) x 3"(H)

- Maximum Box Size: ∞"(L) x 20"(W) x 20"(H)

- Electrical: 110VAC-1PH-60Hz – 10 Amps

- Air: None

- Casters are included in the standard unit.

- Dimensions: 51.5"L x 38"W x 56"H

$4,250.00 -

For Extra Large Boxes

Top & Bottom Case Sealer

- Speed: Up to 2,400 Cases/Hour (65 fpm)

- Minimum Box Size: 6"(L) x 4.75"(W) x 4.5"(H)

- Maximum Box Size: No Max(L) x 27"(W) x 37"(H)

- Electrical: 110VAC-1PH-60Hz – 10 Amps

- Air: None

- Casters are included in the standard unit.

- Dimensions: 51.5"L x 38"W x 56"H

$5,325.00 -

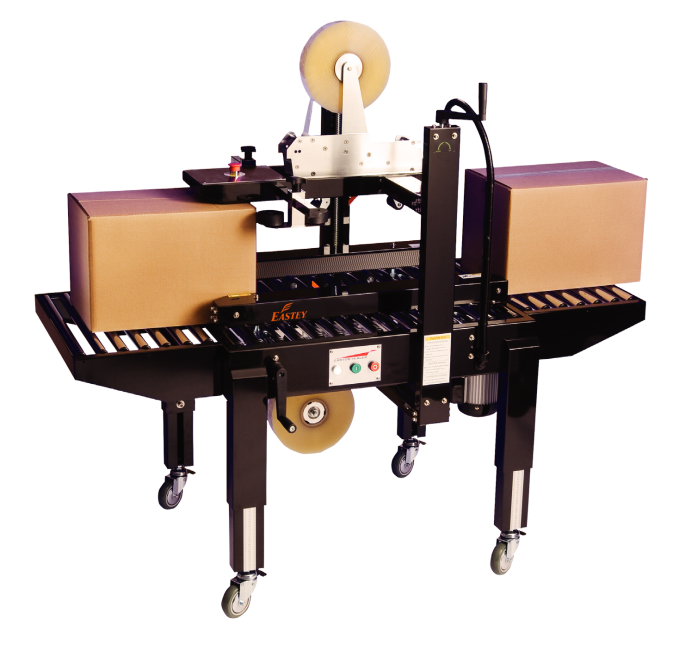

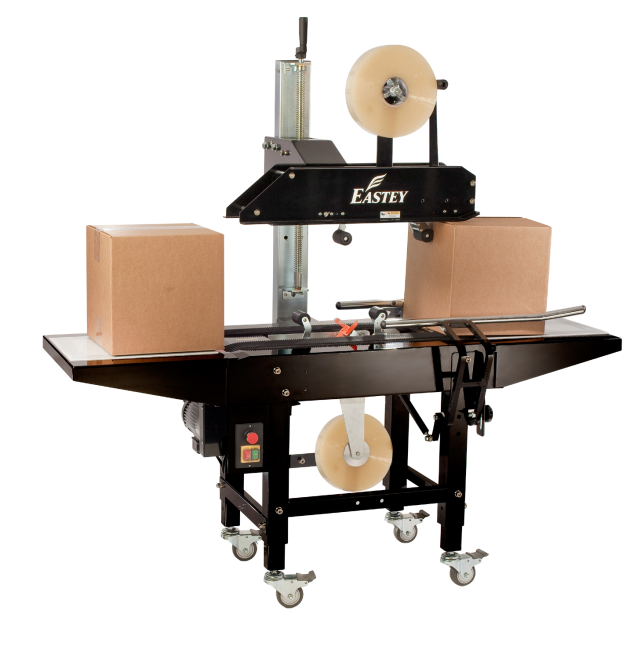

Top & Bottom Case Sealer

Semi-automatic carton sealers are great to have on hand if you need to pack many boxes of different sizes. With intuitive, easy-to-use functions, these box tapers are fast and efficient to help you save time and money. These smart carton sealers are adjustable and create clean, uniform seals across any carton. Simply and quickly adjust the machine to the width and height of the box you're sealing and it will apply the same amount of tape to each box. They're designed to work best when sealing many boxes of the same size during each product run.

- Drive: Top and Bottom Belts

- Minimum Box Size: 5.9"(L) x 6.5"(W) x 5"(H)

- Maximum Box Size: 19.6"(W) x 19.6"(H)

- 2 Heavy Duty 120 Watt Motors ( Competitors use 90 watt motors )

- Belt Speed: 59'/ minute (18m/min)

- 2 " Tape Heads (3" Tape Heads optional)

- Power: 110V 60HZ

- Breaker Switch ( Not found on competitors machines )

- Emergency Stop

- 4 Casters ( Included )

- 16 inch Infeed/Exit Tables ( Included )

As low as $2,395.00 -

- Bottom Belt Drive

- Minimum Box Size: 5"(L) x 6"(W) x 4"(H)

* May be able to run smaller boxes with testing - Maximum Box Size: ∞"(L) x 21"(W) x 20.5"(H)

- Single drive motor

- Tape Speed: 30 cases/min

- Belt Speed: 60ft/min

- Power Supply 110 VAC, 60Hz, 6A

The BB-2 Bottom Belt Industrial Case Taper is a cost-effective top and bottom case taper designed for large run case sealing. The BB-2 utilizes pressure-sensitive tape and features self-centering side rails, a rugged bottom belt drive, and heavy-duty mast that easily adjusts to handle a variety of case sizes.

As low as $4,325.00 -

- Minimum Box Size: 7"(L) x 7"(W) x 4"(H)

- Maximum Box Size: 23.5"(L) x 19.5"(W) x ∞(H)

- Emergency stop switch

- Locking casters

- Air: 1 CFM at 60 PSI

- Electrical: None required

- 1 year on parts

$8,390.00 -

Pneumatic conveyor small capacity pellet loader kit. Aluminum pneumatic loader with control panel and 1.25" inlet. Includes 15' grounded flexible hose, 36" aluminum pick-up wand. Ideal for feeding plastic extrusion machines and similar applications.

Best for materials that have no dust, such as clean pellets.

$2,725.00 -

The side belt driven Easy Packer is designed for compact, packing and sealing. The durable design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum. The Easy Packer provides a fast and cost-efficient alternative to hand taping.

- Side Belt Drive

- Minimum Box Size: 5"(L) x 4.5"(W) x 4.5"(H)

- * May be able to run smaller boxes with testing

- Maximum Box Size: ∞"(L) x 19.5"(W) x 19.5"(H)

- Dual 1/4 HP motors

- Tape Speed: 20 cases/min

- Belt Speed: 75ft/min

- Power Supply 110 VAC, 60Hz, 6A

As low as $8,950.00 -

4.0 - 33.5 oz / 120ml - 1000ml

$4,675.00 -

0.34 - 2.0 oz / 10ml - 60ml

$3,609.00 -

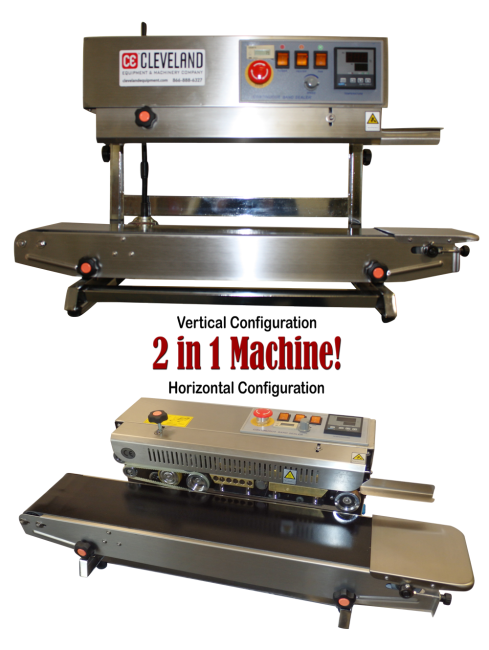

with Emboss/Imprint Wheel

Cleveland Equipment’s CE-2500 Continuous Band Sealer is an ideal Two-in-One Bag Sealer Machine!

If you’re looking to streamline your operation, you’ve come to the right place. Our continuous band sealer machines can make your processes more efficient. Read on to learn a bit more about how a continuous bag sealer machine can benefit your operation.

What is a Continuous Sealer?

A continuous band sealer machine is a commercial appliance that uses heat and pressure to seal bags or packages. Also known as a conveyor sealer, a belt sealer, or a bag and seal machine, these machines simplify your processes.

Since conveyor belt heat sealers are automatic (or semi automatic), they can function on a continuous basis. This means that they require minimal input from an on-site operator, and can function according to their settings. The settings of a commercial bag sealer are adjustable, enabling you to seal a range of packages.

This results in a safer operation, since there is less potential for human error.

If you’re in need of sealing pouches of different sizes, no problem. Specifically, if your operation only requires a small bag packaging machine, we have you covered. Regardless of size, each belt sealing machine applies a consistent and appropriate amount of heat and pressure. The result is an air-tight, hermetic seal.

Benefits of a Conveyor Heat Sealer

Consistency and efficiency are the most often touted benefits of incorporating a continuous band sealer into your workflow. But the benefits go on and on. For starters, continuous bag sealing machines add speed to your operation. If you have a high volume of bags or pouches to seal, a conveyor sealer will get the job done.

Being in control of your speed also puts you in more control of your output. It’s easier to plan for the future if you have a firm grasp of your production rate.

The CE-2500 Continuous Band Sealer specifically makes use of both vertical and horizontal configurations. This means additional options and control over your workflow. It also eliminates the need for two machines. After all, facility space can be tight, and streamlining as much as possible is the goal.

Another specific detail pertaining to the CE-2500 is that it has an embosser wheel. This feature enables you to date or code your packaging on the spot. This keeps your operation organized and continuously up to date, leaving no room for confusion.

$987.00 -

Model CE-975 voltage 220V 60HZ Sealing Current Static 2A / Dynamic 10A Power 2000W Capacity 1-30 ft. / min Sealing Diameter 0.75" to 4.75" Height of bottles 1.57" to 15.5" Machine weight 155 lbs Machine size 61" x 22" x 53" Conveyor height from floor 31.5" $4,259.00 -

Cleveland machinery manufactures standard conveyors for all our machines as well as custom conveyors for all of our customers. All of our conveyors are manufactured in stainless steel and have tool-less guide rail adjustments. We stock 4.5 and 7.5 inch straight conveyors in 10, 13, 16 and 20 feet lengths.$0.00

-

The SB-2EX AUTO is an automatic uniform side belt case taper designed to close all four top case flaps and seal the top and bottom. The adjustable plow system provides the utmost flexibility for varying types of carton sealing applications and provides a great alternative to hand taping. The SB-2EX AUTO will seal up to 20 cases per minute.

- Bottom Belt Drive

- Minimum Box Size: 5"(L) x 4.5"(W) x 4.5"(H)

* May be able to run smaller boxes with testing - Maximum Box Size: 24"(L) x 19.5"(W) x 19.5"(H)

- Dual 1/4 HP drive motors

- Tape Speed: 20 cases/min

- Belt Speed: 75ft/min

- Power Supply 110 VAC, 60Hz, 6A

As low as $11,900.00 -

1.0 - 4.0 oz / 30ml - 120ml

$5,769.00 -

1.5 - 8.5 oz / 45ml - 250ml

1.5 - 8.5 oz / 45ml - 250ml$6,049.00 -

4.0 - 33.5 oz / 120ml - 1000ml

$7,255.00 -

Cleveland expandable pressure–overflow filler model CE-33, automatic inline filling machine (No nozzles, conveyor, or options included):$18,285.00

-

The machine features one (1) seal bar that is approx. 10" wide. The open area in the chamber is about 10" x 13.5" (this does not include the area taken up by the seal bar). Simply set the optimal vacuum time, sealing time, cooling time, and sealing temperature for your bags and away you go.$949.00

-

-

18.5 - 169.0 oz / 500ml - 5000ml

18.5 - 169.0 oz / 500ml - 5000ml$8,417.00 -

Multi-purpose machine can be used for both polyethylene and barrier film applications. Sealing is accomplished by the material passing through two 10" heated bars separated by Teflon sealing bands.

- Feed Direction

- Right to Left

- Left to Right

- Seal Width

- 3/8" or 3/4" standard; 1/8", 1/4", or 1/4" double seal optional

- 3/8" or 3/4" standard; 1/8", 1/4", or 1/4" double seal optional

- Sealing Capacity

- 6 mil single thickness gusseted bags

- 12 mil single thickness flat bags

- Temperature Control

- 600 ± 2 ºF

- 600 ± 2 ºF

- Speed

- Variable speed up to 750 inches per minute

$11,999.39 - Feed Direction

-

Top & Bottom Case Sealer

- Drive: Side Belts

- Minimum Box Size: 7.9"(L) x 5.9"(W) x 4.7"(H)

- Maximum Box Size: 19.6"(L) x 19.6"(W) x 19.6"(H)

- Heavy Duty 200 Watt Motors (2)

- Belt Speed: 59'/ minute (18m/min)

- Power: 110V 60Hz

As low as $6,379.00 -

CE-15 Automatic inline bottle cleaner machine (conveyor or options included):$31,375.00

-

- Simple to operate

- Heavy Duty Construction

- LCD Screen and PLC

- Programmable wrap pattern

- Single button automatic cycle start

- Emergency stop button

- Variable film carriage speed

- Auto load height photo-eye

- Manual controls

- Max Pallet Size: 50” W x 50” L x 98” H

- Machine Dimensions: 96.5" L x 59" W x 109.5" H

- App. Shipping Weight: 1,300 Lbs.

- Power Requirements: 120V / 1Ph / 15A Dedicated Service

- Maximum Load Weight: 4000 Lbs

$9,895.00 -

with Ink Print Wheel

Two in One Bag Sealer Machine!

Horizontal / Vertical Configurations with Ink Print WheelThe CE-3000-HVE Continuous Band Sealer with built-in printer is a great bag sealer for small- and large-scale companies that want reliability and versatility at once. Featuring a unique configuration that allows it to sit both vertically or horizontally, this high-quality bag sealer also uses an electronic temperature control system and a speed adjusting transmission to give the user all the control. These top-quality machines are designed to work with bags up to 18 inches tall and even feature built-in solid-ink coding devices that print clear characters on the package in instant-dry permanent ink. Our band sealers can handle various types of plastics, including mylar, single or composed bags.

The standard machine will seal a bag vertically 10"-18" H. With the height reducing bracket the machine will seal a bag vertically 4"-10.5" H.

- Stainless steel

- 3/8 in. Seal Width

- Digital Temperature controller

- Speed controlled conveyor

- Counter

- Emergency stop switch

- Ink Print Wheel

- Minimum Vertical Bag Height - 4" with height adj bracket

10" standard unit - Maximum Vertical Bag Height - 10."with height adj bracket

18" standard unit - Optional Stainless Steel Stand ($275)

$1,295.00 -

(Min) 1ml - (Max)1.4 Liters

- Type of Machine: Bottle Filler / Gear Filler

- Construction: 304 Stainless Steel Food Grade Standard

- Seals: Buna Food Grade Standard (See Separate List for Sizing)

- Tubing: Silicone 7/16 Inch OD

- Valve: ¼"

- Spring: Stainless Food Grade Standard

- Output: (Min) 1ml - (Max)1.4 Liters

$2,174.00 -

(Min) 5ml - (Max)10 Liters

- Type of Machine: Bottle Filler / Gear Filler

- Construction: 304 Stainless Steel – Food Grade Standard

- Seals: Buna – Food Grade Standard

- Tubing: 5/8 inc OD

- Valve: 3/8â€

- Spring Stainless – Food Grade Standard

- Output: (Min) 5ml - (Max)10 Liters

will fill 35qty 1-Oz bottles of water in 60 seconds

$2,173.00 -

This semi-automatic capper machine has speeds of 20-25 bpm, and is designed for 22-110 mm screw caps and bottle heights ranging from 50-260 mm. With an adjustable capping height (as well as speed), this screw capping machine has the flexibility you need.

Featuring a stainless steel body along with stainless steel stand and casters, this machine has the strength and durability your process requires. Additional benefits to this design are such features as a sensor detection system. This means that if there is no bottle, then no capping occurs.

This machine also has a microprocessor, enabling user-friendly control, as well as an emergency stop button.

It is important to note that caps have to be fed manually into this machine. It should not be washed down. Instead, it needs to be wiped down when cleaning. Here is some additional information and reviews pertaining to this bottle capping machine:

- Capping speed: 20-25 bpm

- Suitable for 22-110 mm screw cap

- Bottle height: 50-260 mm

- THIS IS NOT A WASH DOWN UNIT. IT IS A WIPE DOWN UNIT ONLY

$14,025.00 -

(Min) 5ml - (Max)10 Liters

- Type of Machine: Bottle Filler / Gear Filler

- Construction: 304 Stainless Steel Food Grade Standard

- Seals: Buna Food Grade Standard

- Tubing: 5/8 inc OD

- Valve: 3/8"

- Spring: Stainless Food Grade Standard

- Output: (Min) 5ml - (Max)10 Liters

will fill 35qty 1-Oz bottles of water in 60 seconds

$3,807.00